FPC film key switches need to undergo strict factory testing processes before entering the market to ensure that their electrical performance, mechanical life, and appearance quality meet industry standards. The overall inspection covers three stages: raw material acceptance, in-process sampling, and full inspection of finished products, ensuring the stability and reliability of each batch of products.

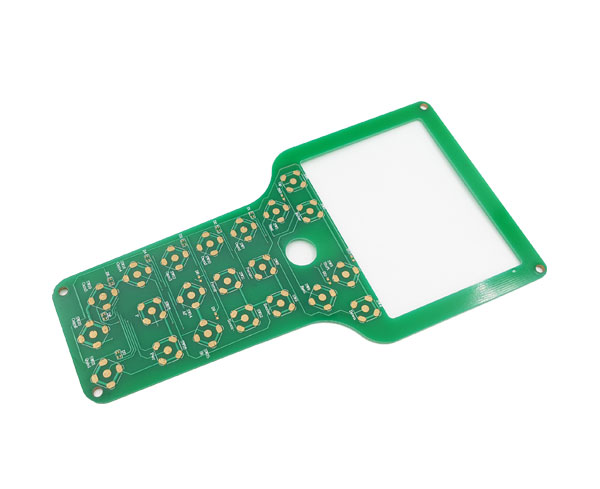

In the material warehousing stage, the physical performance and environmental protection indicators of FPC base material, conductive ink, facial mask adhesive layer and other items need to be tested. After entering the production process, each key process such as printing, hot pressing, die-cutting, and circuit testing is equipped with process control points to ensure dimensional accuracy, circuit integrity, and no deviation in key function.

In the finished product stage, multiple tests such as conductivity resistance testing, tactile consistency calibration, high and low temperature aging, and electromagnetic compatibility verification are required. Button lifespan testing often uses an automatic impact platform to simulate tens of thousands of presses and test its elastic recovery and conductivity stability. Appearance inspection includes key items such as printing clarity, stack offset and surface bubbles to ensure that the facial mask is beautiful, free of degumming and stains.

Some customized products also require functional orientation testing and customer project review to ensure good performance under specific application conditions. The entire testing process follows ISO quality system standards to ensure that the delivered products meet industrial grade usage requirements.